Raku, How to ?

|

The 6 processes for a good raku are: clay process, Bisque process, glazing process, fire process, sawdust process, cleaning process. Process 1 Use a clay ready for raku (stoneware with 15 to 30% grog). Build your bowl (or anything else) enough thick. Let it dry. |

Process 2 : The Bisque Process You can bisque (1830° F) in an electic or gaz kiln. Don't bisque to hight (1920° F max) or the clay will be too contracted.If you'r using your raku kiln, follow these steps: 0 to380° F in 2 hours, 380 to 1100 °F in 3 hours, 1100 to 1830 in 2 hours, wait 4 h to open your kiln.Total process need 7 h for burning. |

|

|

Process 3 : The Glazing Process Use simple glazes, thin.Do'nt forget ! parts of your pots without glaze will be black. To have a simple transparent glaze, use this base recipe: mix 85% of alkaline fritt (ie: ceradel 1254) and 15% kaolin. If you want copper luster, add 6% copper oxyde and 3% ferric oxyde (I know it'is 109% but that ceramics cooking !!!). |

|

|

Process 4 : The Burning Process If it is the first firing,increase temperature slowly (20 mn to 392° F) then fire quickly to 1700-1800 ° F (about 1 h). During this time, prepare the sawdust,a big metallic container and a bucket of water. When 1700-1800 ° F, stop the burner, open the door of your kiln. |

|

|

Process 5 : The sawdust Process When it's red, get your pieces whith tongues, and put them in a metallic container. If you want crackels, wait 40 seconds. then cover the piece with sawdurst. Close the container with his top. Wait 5 to20 minutes (it depends if you want dark blacks or not). You're ready to clean now |

|

|

Process 6 : The cleaning Process Get your piece from the container. soak it in water to stop the chimicals reactions. When it is cold, clean it with a sponge or a metallic sponge. |

|

|

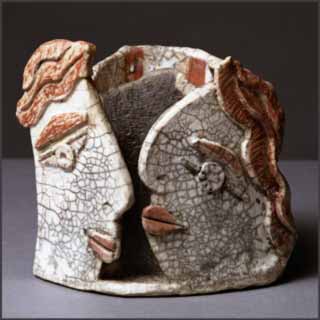

Process 7 : Admire |

|

Nota: faits et lieux sont purement imaginaires !!

Nota: facts and places are a pure product of my imagination !!